Eng Yee is using a technology by Reverte, "Oxo-biodegradables" which is an environmentally friendly technology to help in reducing the impact of plastic waste on the environment.

How good it is?

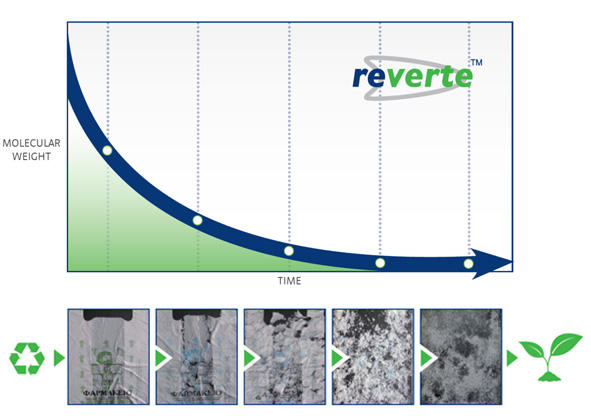

The term ‘Oxobiodegradability’ is a hybridisation of two words, oxidation and biodegradability. It defines clearly a two step process initiated in this case by the Reverte® additive to degrade the polymer chain (break up) and make it available for biodegradability within the environment when a treated item has finished its useful life.

Reverte® is introduced to a plastic article such as a check out bag at the manufacturing stage, the complex formulation is dosed in at a very low level, and the carefully developed complex additive package within Reverte® is now within the plastic at a predetermined amount.

Study of a Reverte® Checkout Bag

It is a common misconception that this resultant powder is just smaller pieces of plastic, this is not the case. The molecular weight has dropped and oxygen has been introduced into these species, producing a complex mixture of carboxylic acids, ketones and alcohols. These lower molecular weight entities are not polymeric (the do not have sufficient repeating units to be classed as a polymer) and the material does not have any of the plastic properties which we associate with the polymer. It has therefore irreversibly changed beyond recognition.

Using a checkout bag offers the consumer a convenient way of carrying their goods from the shop, and a bag which can be used for a second time, either to collate trash or recyclate. It has been shown in a number of studies that banning a checkout bags sends the sales of bin liners and trash bags through the roof, hardly a reduction in the use of plastics that such a ban is intended to achieve!

Reverte® when incorporated into the checkout bag at the point of manufacture ensures that if the bag at the end of its useful life is irresponsibly discarded, will not pose a long term environmental problem or hazard.

The formulation is devised to allow sufficient time for the bag to become part of a collection scheme and recycled into another application such as artificial timber planks, or for it carry out a second task such as waste bag then rapidly degrade.

*Customer actually won't face any temperature problem when having this technology in the plastic products. |